|

|

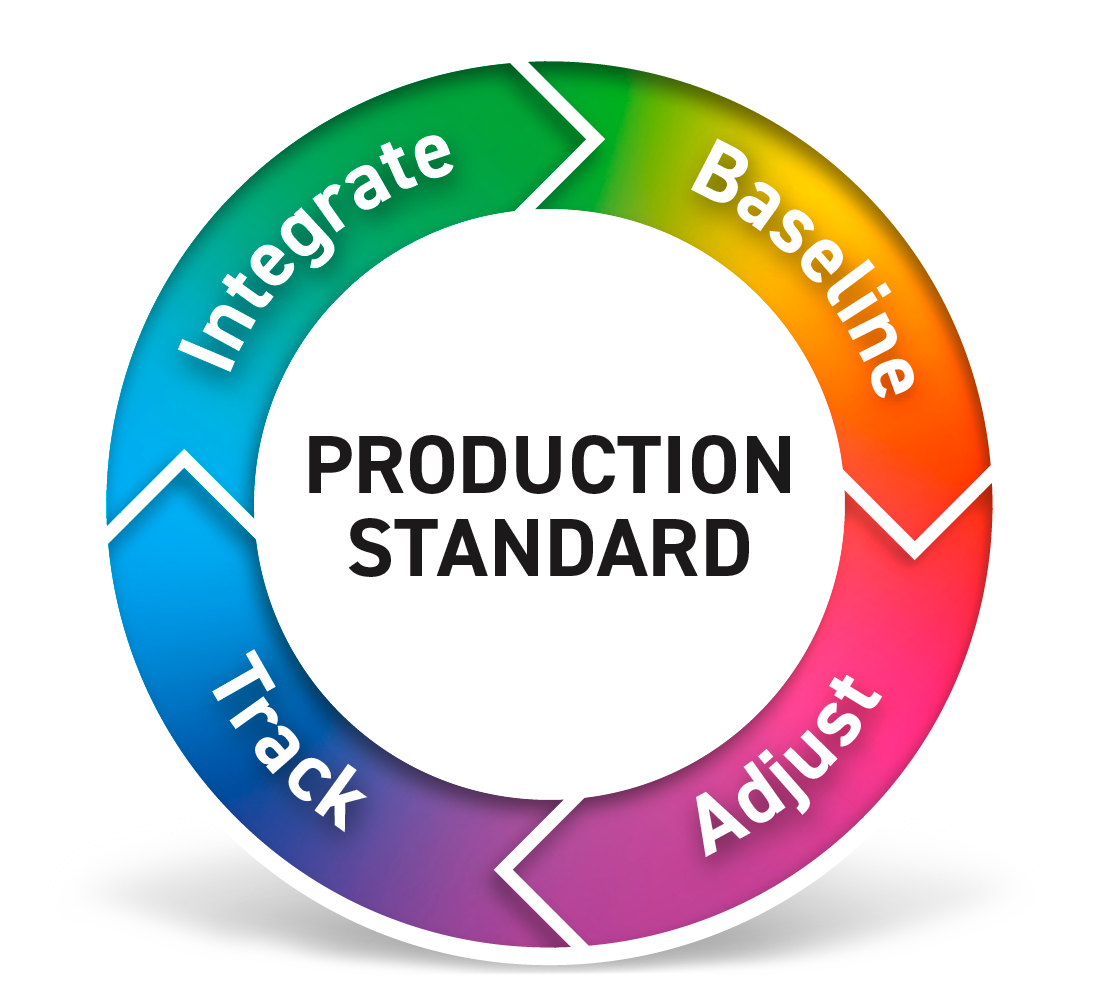

ChromaChecker – 5 steps to Color ConformanceProduction Standard + Baseline + Adjust + Track + Integrate

|

|

|

|

|

|

| Print Manufacturing | Brand & Print Buyers | Color Manufacturing | Packaging Production |

|

Control all variables affecting the production process. Balancing production with the required production standards to meet customer expectations. |

Synchronizing quality control process across the supply chain ensures the highest quality results to achieve the goal |

Ensuring the color and appearance meet expectations when rendering color on textiles, plastics, paint, metal, liquids, and more. |

Advanced tools supporting project management, packaging production and quality control. > SOON < |

|

|

|

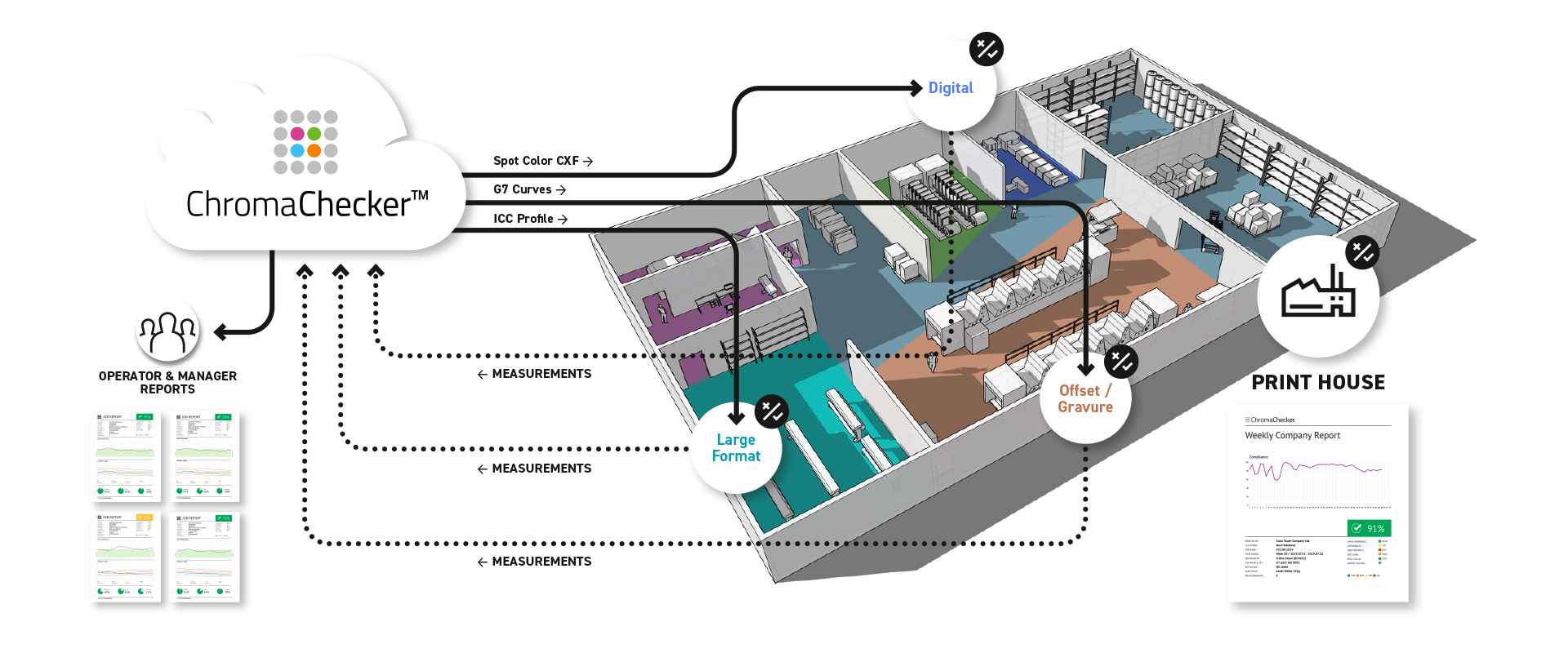

ChromaChecker allows you to achieve and maintain the required level of color reproduction and track it over time – it is the industry's first Color Conformance Platform, which enables a printer to establish its own production standard that meets customer expectations. It is compatible with virtually all software that printers use for proofs and presses, so operators don’t have to change the way they work. |

|

ChromaChecker is officially an Idealliance G7® Certified System. If you need your print facilities to get qualified as a G7® Master Printer, ChromaChecker can do it! G7® Calibration is just one of more than fifteen tools available in your favorite Cloud-based Print Quality System. |

ChromaChecker guides the user to define desired expectations and then determines if the printers can deliver that level of color conformance and, if not, adjusts the printer to improve results. |

|

Provides a unique method of assessing customer Production Standard requirements

If the print device's E-Factor is less than or equal to expectations – print is salable |

|

E-Factor is based on delta E (∆E 00) metrics but for communicating visual differences related to two pages compared to one another. When comparing two color samples, the industry uses ∆E formula. This approach is only good for single-color comparisons. When comparing pictures or pages with thousands of colors (think of each dot/pixel in a picture being a different color), ∆E metric doesn't work. But a derivative of ∆E called CRF at the 95th percentile does work extremely well when comparing hundreds or thousands of colors. This formula eliminates 5% of the highest ∆Es, ensuring that 95% of the colors between the images are within the ∆E at the 95th percentile. This metric, called E-Factor, co-relates directly with the relative difference when using ∆E for single color comparisons but applies to visual differences between two pages or images. |

Print Color Reproduction is never perfect – Find out

|

|

|||

|

Personal E-Factor Blind Exercise |

E-Factor Sampler Exercise |

What Our Users Say About Us |

||

Digital Room Inc.Established over twenty years ago, a leader in B0px 2B online printing, Digital Room Inc has offered customized printing and marketing collateral to small and medium-sized businesses. Operating through a network of four manufacturing plants, the company prints and delivers over one million orders each year. They earned the trust of thousands of design and marketing professionals, with two-thirds of their business from repeat customers. |

Coburn Carton SolutionsFor almost five decades, Coburn Carton Solutions has steadily grown to provide the finest packaging to some of the world’s biggest brands with printing and folding carton solutions. Coburn’s breadth of expertise, technology, and experience provide the level of service their leading brands customers require for delivering carton solutions that command in-store attention. |

Alder Color SolutionsOnce I began using Chromachecker to create G7 Curves, I realized I could use their CC84 3 Row Control Strip to generate the curves which is MUCH quicker than measuring a P2P chart in Chromix. In addition, the end results were noticeably better. (…) And that's just the tip of the iceberg with Chromachecker. |

> Check out other opinions and experiences from our users |

||

Experience ChromaChecker in action

| Spot Color Exercise | Image Color Exercise | E-Factor Blind Exercise | Web Browser Tester |